| 아니 | 장비 이름 | 단위 | 양 | 주요 기능 |

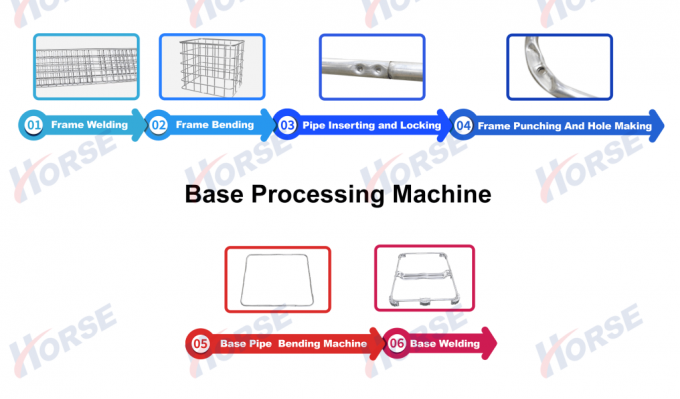

| 1 | Mesh gantry 용접 기계 | 단위 | 1 | 복수점 젤리 용접 |

| 2 | 자동 격자식식 기계 | 세트 | 1 | 길고 짧은 튜브의 자동 충전 |

| 3 | 매스물 취출 조작기 | 단위 | 1 | 매시 풀기 (배치) |

| 4 | 4축 굽기 기계 | 세트 | 1 | 회축머리로 된 망원경의 구부림 및 형성 |

| 5 | 잠금기 | 세트 | 1 | 매체의 굽기 및 얽힘 |

| 6 | 평평화 펀싱 기계 | 세트 | 1 | 프레임 아래의 바닥 파이프의 펀칭 및 절단 |

| 7 | 프레임 조작기 | 세트 | 1 | 프레임을 잡기 위해 위아래로 움직이는 3개의 조작기 |

| 8 | 강철 발 용접 기계 | 세트 | 1 | 바닥 프레임의 강철 발의 용접 |

| 9 | 강철 발 용접 기계 물질을 취하는 조작기 | 세트 | 1 | 용접 후 바닥 프레임의 추출, 이전 및 쌓기 |

| 10 | 자동 밀폐 기계 | 세트 | 1 | 선반의 밀착성 검사 |

| 11 | 바닥 파이프용 자동 이중 굽기 기계 | 세트 | 1 | 바닥 튜브의 축소, 부각 및 구부리기 |

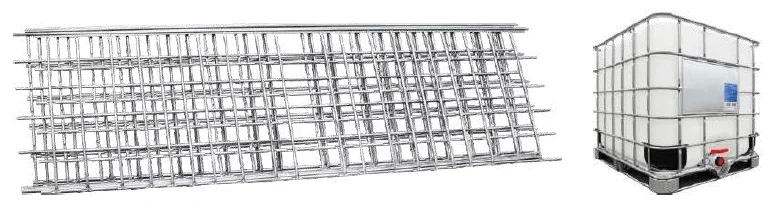

| 12 | 진동 테스트 플랫폼 | 세트 | 1 | IBC 배럴의 견고성과 보호 테스트 |

메시지를 남겨주세요

곧 다시 연락 드리겠습니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다!

이메일을 확인하십시오!

이메일을 확인하십시오!

제출

정보가 많을수록 커뮤니케이션이 향상됩니다.

씨

- 씨

- 부인

승인

성공적으로 제출되었습니다!

곧 다시 연락 드리겠습니다!

승인

메시지를 남겨주세요

곧 다시 연락 드리겠습니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다!

귀하의 메시지는 20-3,000 자 사이 여야합니다!

이메일을 확인하십시오!

이메일을 확인하십시오!

제출